Things you need to know about how to design of mold slide.

Posted on : March 11, 2022 By GREFEE

Undercuts treatment

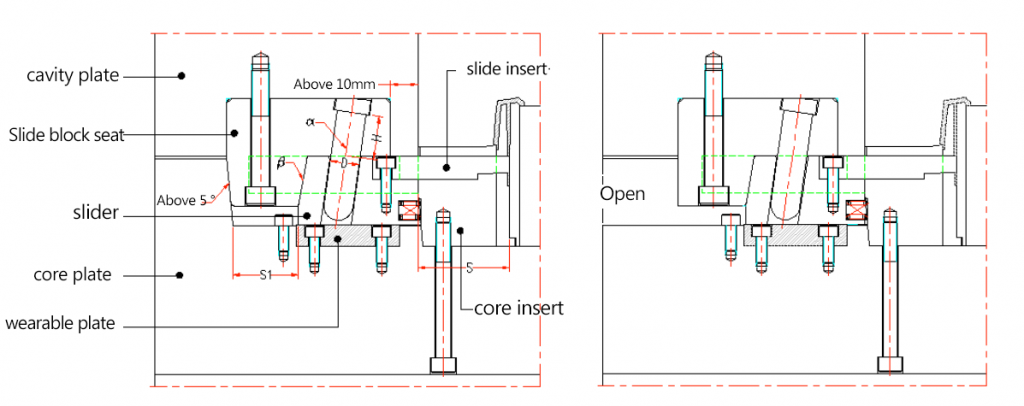

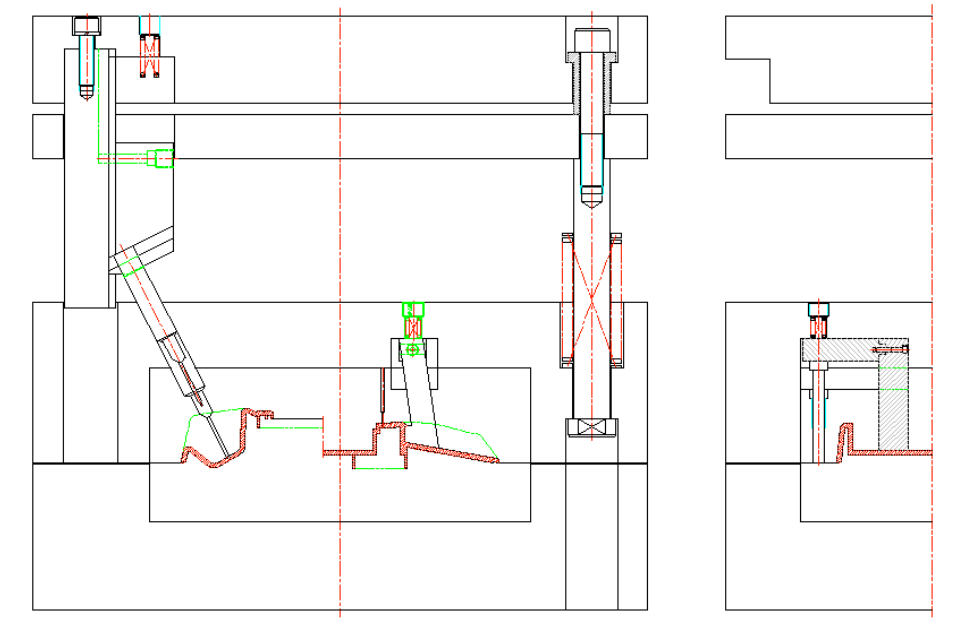

Movement principles & design elements of diagonal bracing pin block

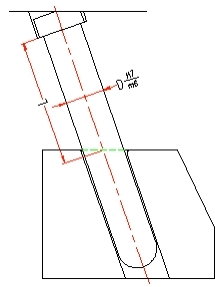

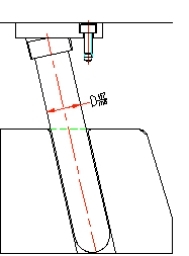

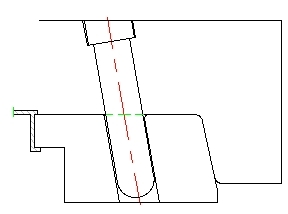

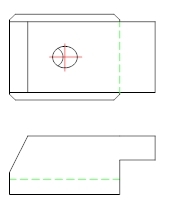

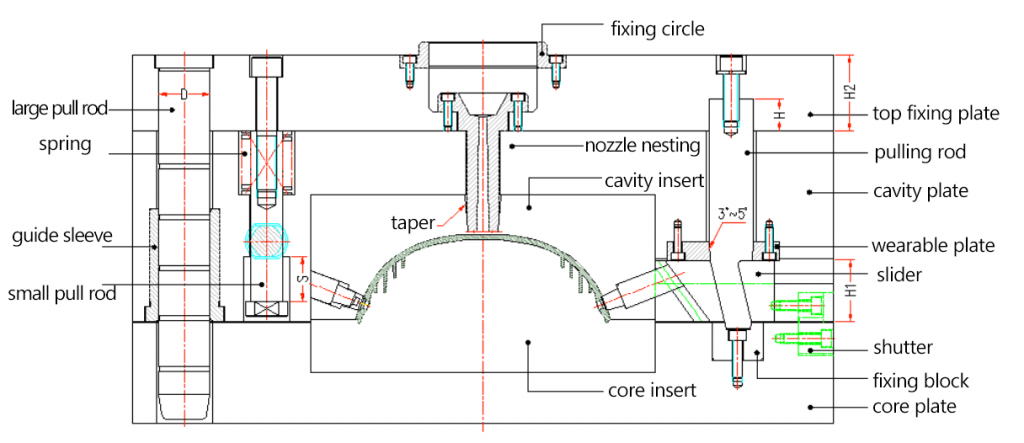

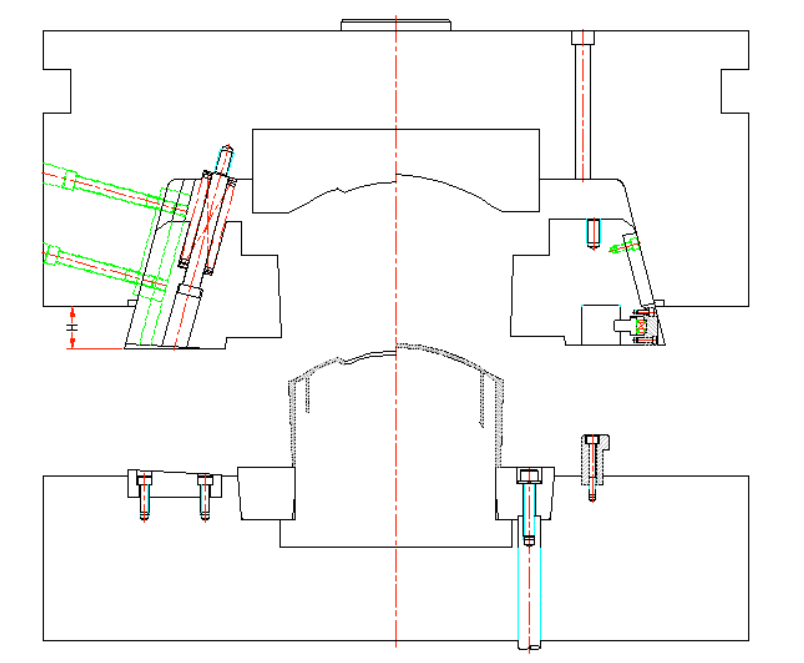

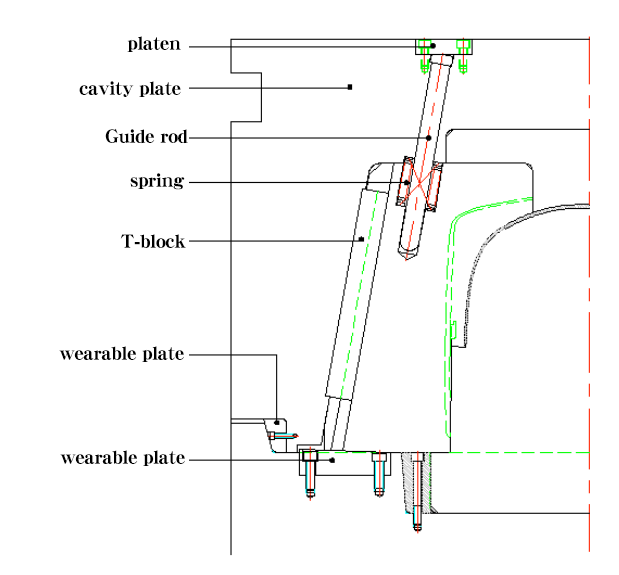

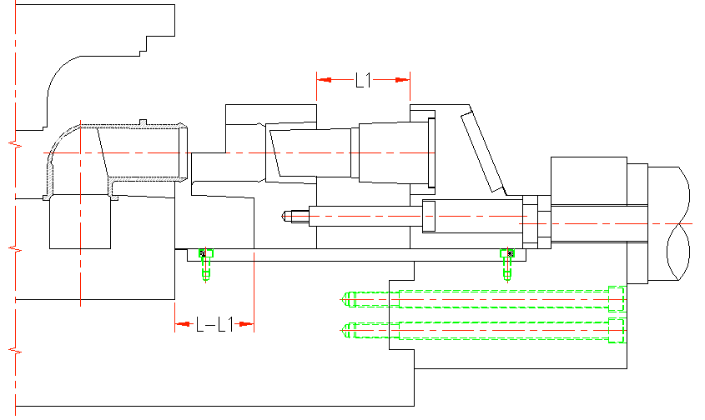

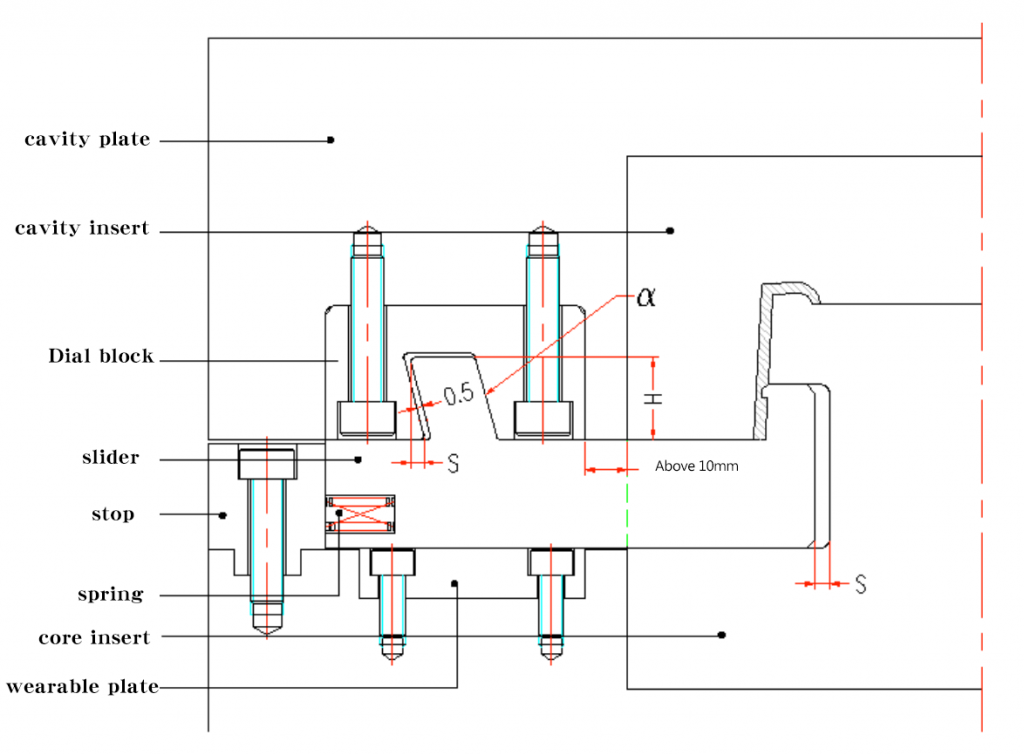

Undercuts treatment uses the mold opening movement and ejection force to causes the tendency of relatively motion between angle pin and slider. There are two movements to make it separate from the undercut : mold opening direction & horizontal direction. As the below pic shows:

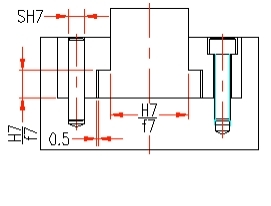

in the pic:

β=α+2°~3°(avoid any parts contacts or blocks when group molding & reduce friction when opening molds)

α≦25°(α is the obliquity of taper pin)

L=1.5D (L is matching length)

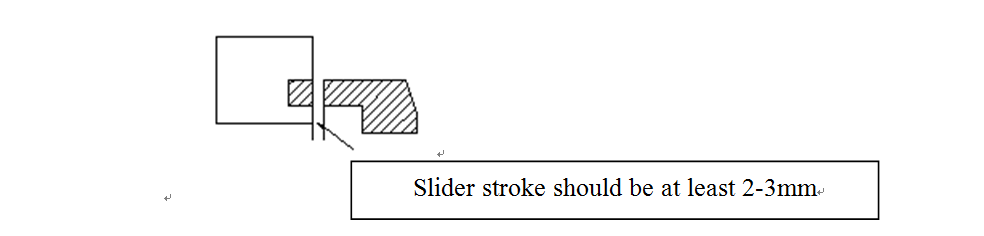

S=T+2~3mm(S, the distance of horizontal movement of slider, T, the end product undercut

S=(L1xsina-δ)/cosα(δ – the space between taper pin and slider, normally is 0.5MM,L1is the taper pin vertical distance inside the slider)

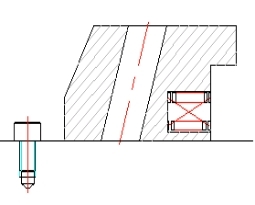

Clamping methods & applicable situations of diagonal bracing tip

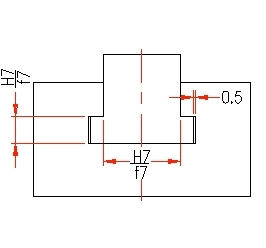

| Diagram | Description |

| Suits for situations, like thin mold and the top clamping plate and cavity plate are closed. The contact area is long and stable. |

| Suits for situations, like thick mold, large mold cavity. applicable to two plate mold/three plate mold.The contact area L≧1.5D(D is diameter of diagonal bracing tip), good stability |

| Suits for thick mold applicable to two plate mold/three plate mold contact area L≧1.5D(D is diameter of angle pin), poor stability, hard to processing |

| Suits for situations, like thin mold and the top plate mold and cavity plate can be separated. Long contact area, good stability |

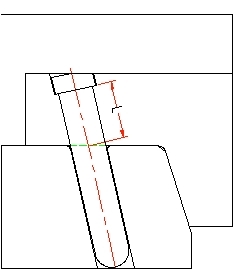

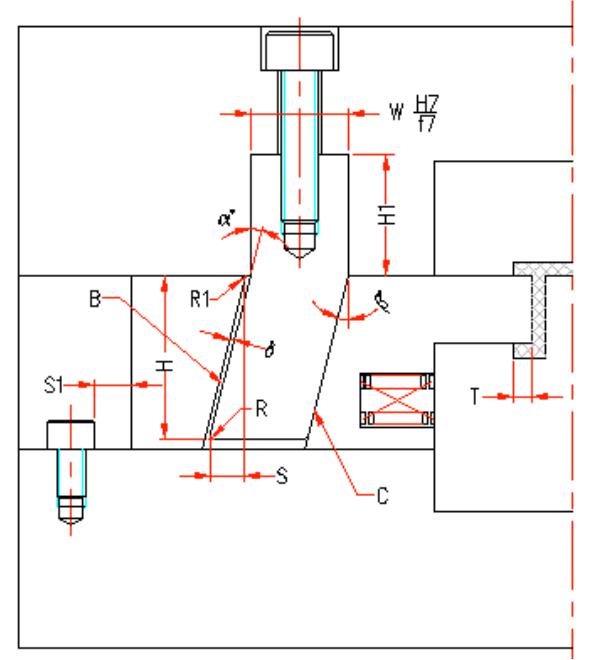

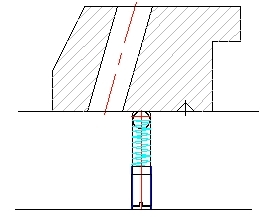

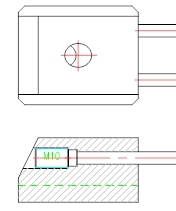

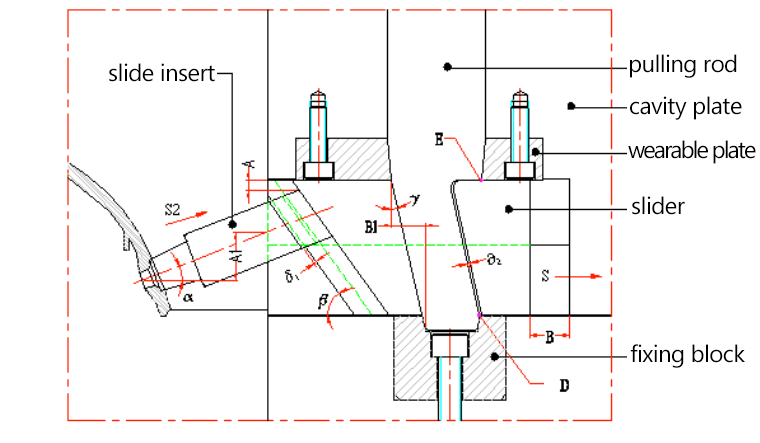

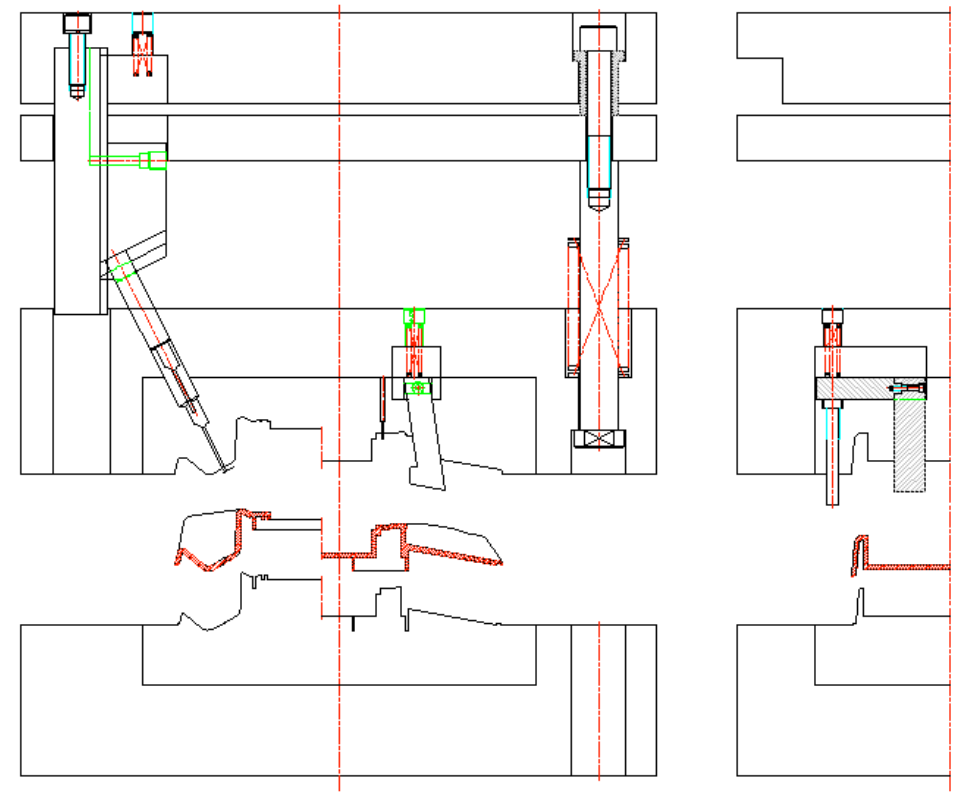

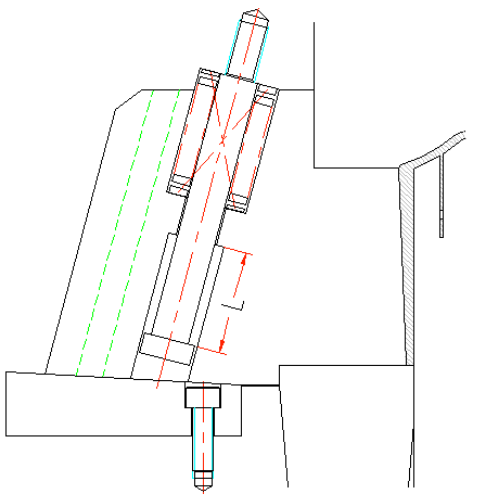

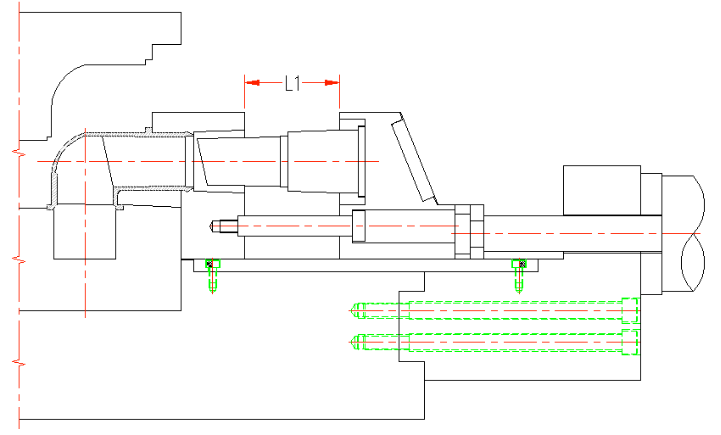

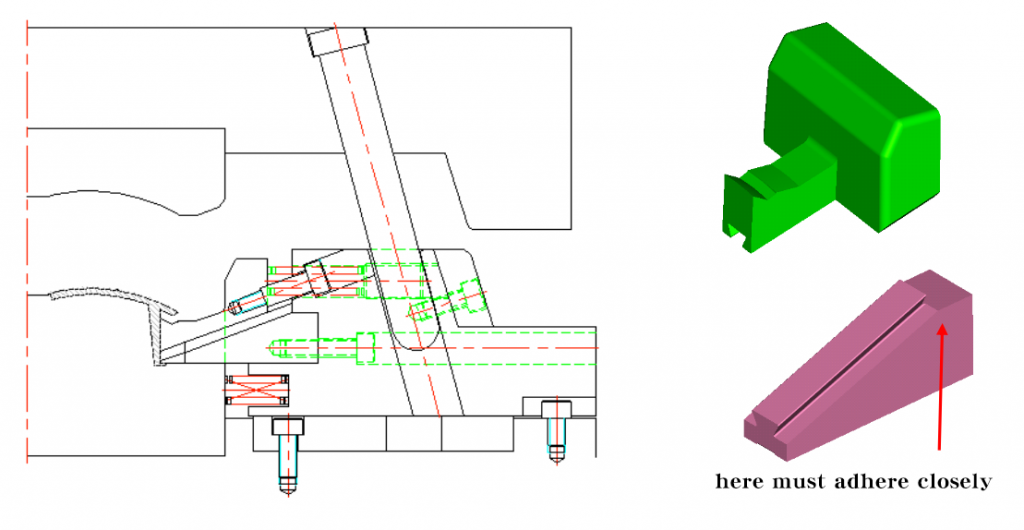

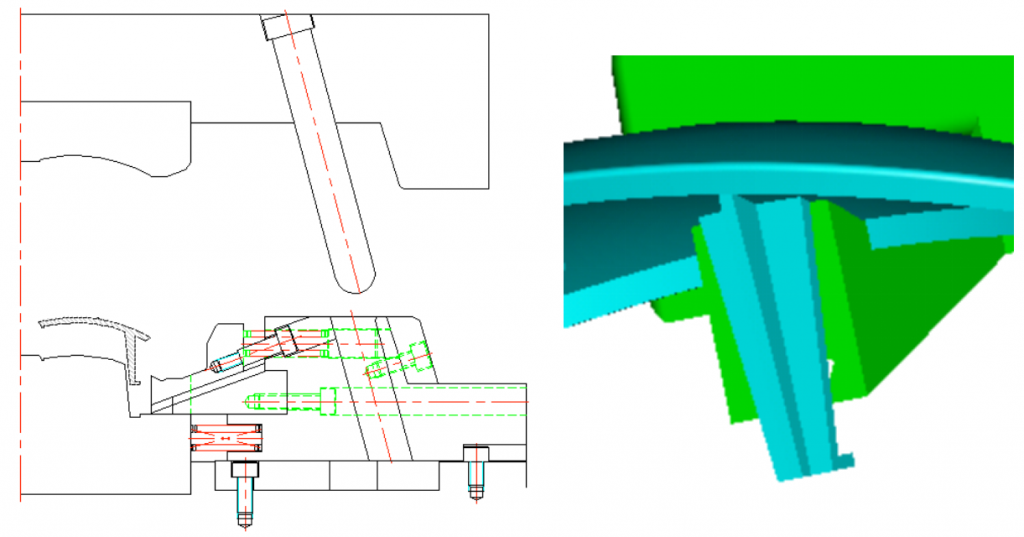

Movement principles & design elements of pulling block

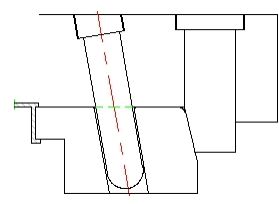

The mold opening movement of molding machine causes a tendency of relatively motion between pulling blocks and sliders.

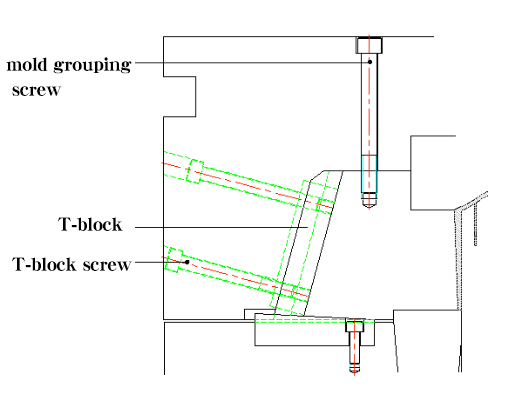

See pic below:

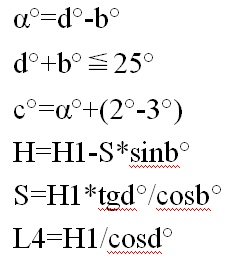

in the pic above:

β=α≦25° (α – the obliquity of pulling block)

H1≧1.5W (H1-matching distance)

S=T+2~3mm (S-distance of horizontal movement of slider, T- end product undercut)

S=H*sinα-δ/cosα(δ – the space between diagonal bracing tip and sliders, normally is 0.5MM,L1is the vertical distance of

H-vertical distance of pulling block inside the slider)

C- motion stopping surface so the pulling block form doesn’t need motion-stoping surface(no space)

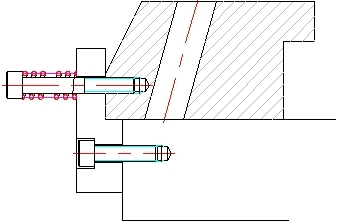

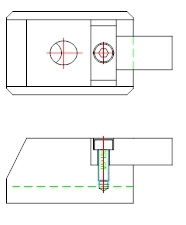

Slider locking & fixing solutions

There is a huge pressure during the molding machine injection process. To avoid affecting the side and appearance(eg. burrs) of end products, we should keep the slider and core unmoved when molding machine injection. So the slider should use locking fixed method to keep it stay. normally, this part is motion-stoping block or heel.

Some common locking methods:

| Diagram | Description | Diagram | Description |

| The sliders are pieced together, normally used for standard products. Normally used standard products, check standard parts catalogue. Good structure and hardness. Applicable to situations needing strong locking force. |  | Use insert mode to lock. Applicable to wide sliders. |

| Use integrated locking mode. Good rigidity and structure. Hard to processing. Short Demolding distance. Applicable to small molds |  | Use insert mode Applicable to wide sliders |

| Pulling or stopping Poor stability Applicable to situations of small slider space |  | Are pieced together Good rigidity Applicable to situations of large space |

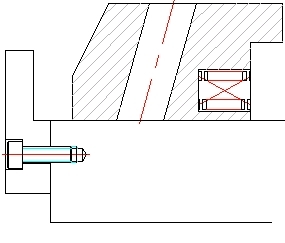

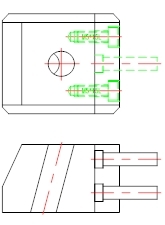

Fixed methods of slider

The slider will move a certain distance in mold opening. One way to make the slider return back smoothly is to use equipment to fix it and it should be flexible and stable so that the slider will stay at where it should be. Some exceptional situations do not need fixed equipments, like left to right slider, so it is suggested to apply a fixed equipment.

| Equipment for fixing: diagram | Description |

| Fixing slider with spring screw, the strength of spring is 1.5-2 times the weight of slider. Applicable to upward or lateral core pulling. |

| Fixed by spring steel ball. Normally for small sliders for lateral core pulling. |

| Fixed by spring screw and guard. Strength of spring is 1.5-2 times the weight of slider. Applicable to upward and lateral core pulling. |

| Fixed by spring guard, Strength of spring is 1.5-2 times the weight of slider. Applicable to big slider, upward and lateral core pulling. |

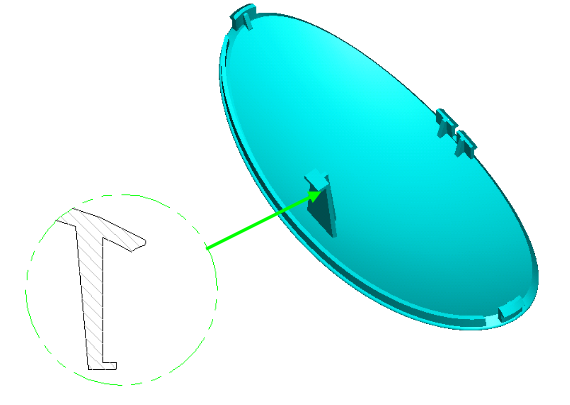

Connecting method of slide insert

How slider head insert connected is controlled by end product. Different end products have different connecting methods.

The slider head insert connected methods details:

| Diagram | Description | Diagram | Description |

| Integrated structure Applicable to situations of large cores, good strength. |  | Fixed by screw. Applicable to situations of cores, round, or cores are small. |

| Fixed by screw. Applicable to situations of square cores/small or medium cores |  | Fixed by screw. Applicable to situations of square cores/small or medium cores |

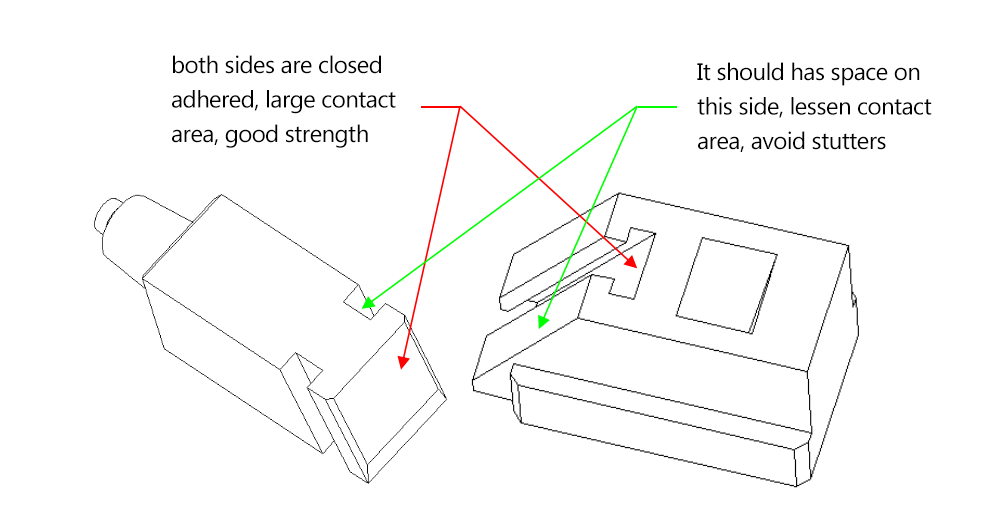

Guide form of sliding block

In the slide guiding, the slider must be smooth and stable so that no stutters or beats, which will affect the aspects, like quality and service life of mold. (Link for the specifications of platen)

The common sliding guide forms are shown in the figure below.

| Diagram | Description | Diagram | Description |

| Integrated manufacturing mode, hard to manufacture, applicable to small mold manufacturing. |  | Clamping plate ¢ral rail mode. Applicable to situations of long slider and high cavity temperate. |

| Rectangle platen. Easy to manufacture. Fine strength, wide range of application, the specifications of platen is on standard parts list. |  | “T” groove inside the slider. Applicable to situations of small space, like slide inside the slider. |

| Applied “7” shaped clamping plate. Easy to manufacture, good strength. normally fixing with pinhole together. |  | Inserted “T” groove, good stability, hard to manufacture. |

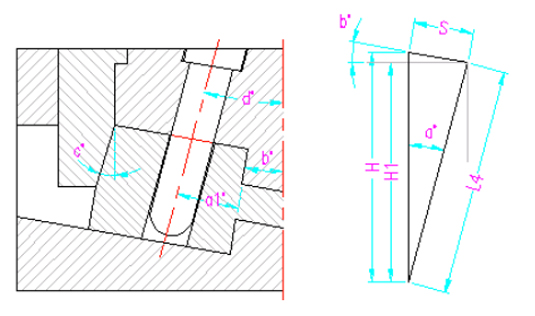

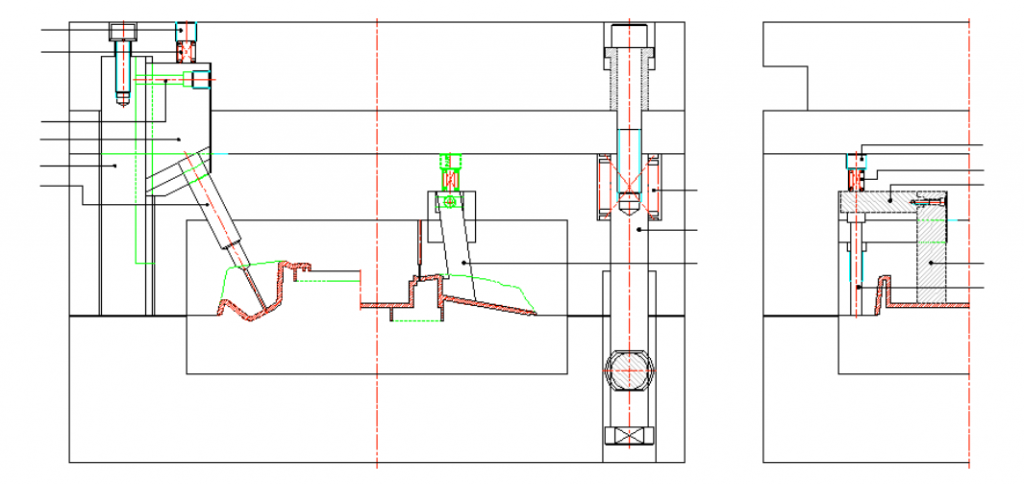

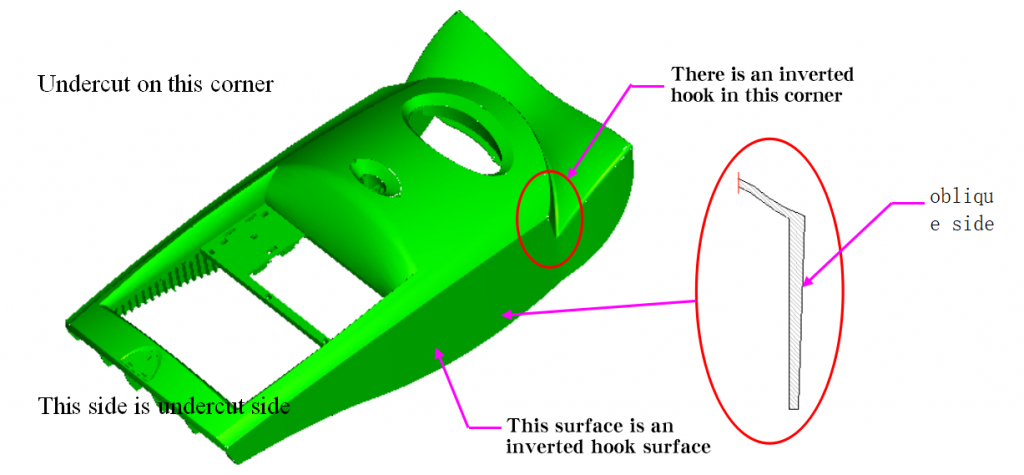

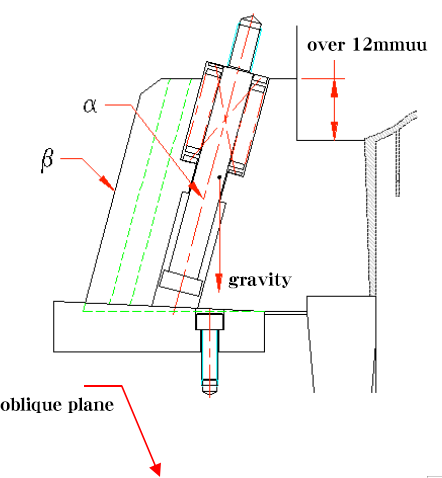

Calculation of tilt slider index

Due to the undercut surface of the end product is tilt, so the move direction of slider should follow the direction of end products’ undercut surface, otherwise it will cause damages when pulling the end product.

When the angle situation between the slider core pulling and the parting surface is called the slider pulling direction moving-die.

Shown as pic:

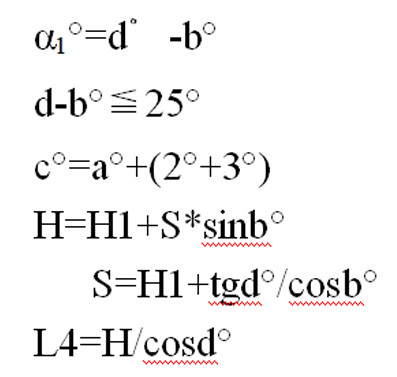

Situation when the angle between slide core pulling direction and parting surface is slider pulling direction fixed-die.

Shown as below:

master mold runner slider

application features:

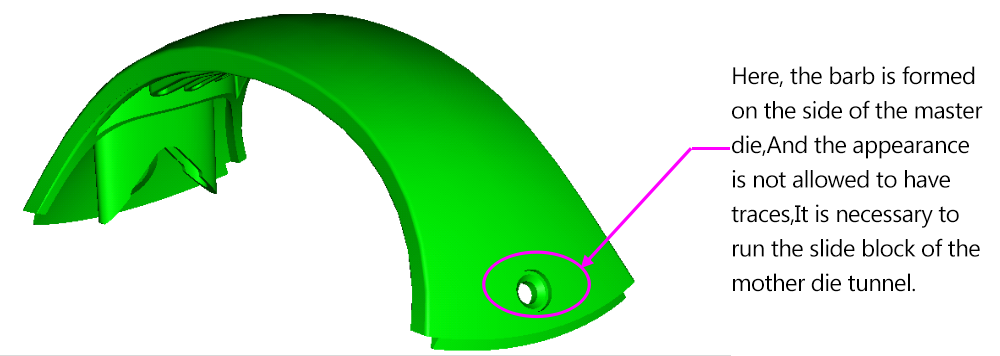

Undercuts forming on the side of master mold

Marks are allowed on the appearance

Medium slider forming area

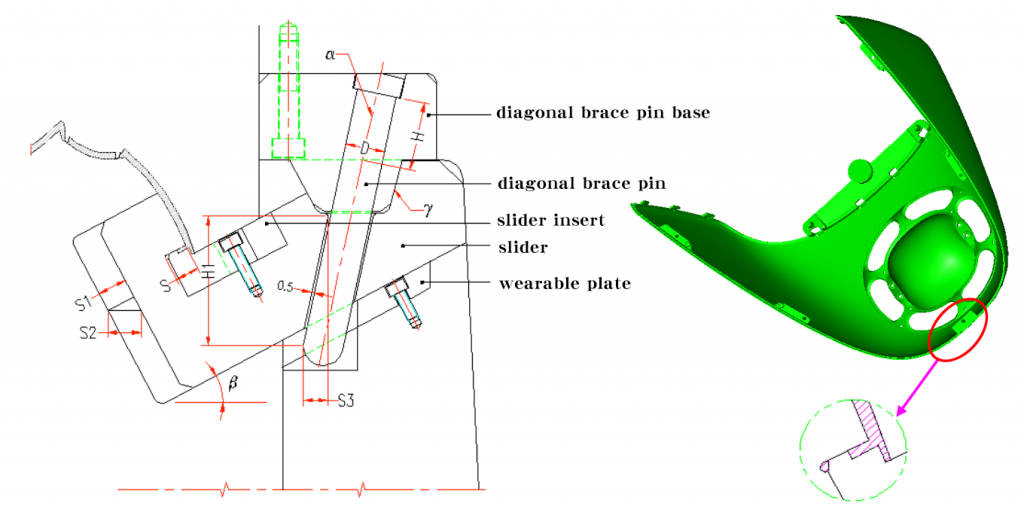

Shown as below:

Undercut forming on the side of master mold. No marks allowed on appearance. Need to switch to master mold runner slider.

Master mold tunnel block shown as below:

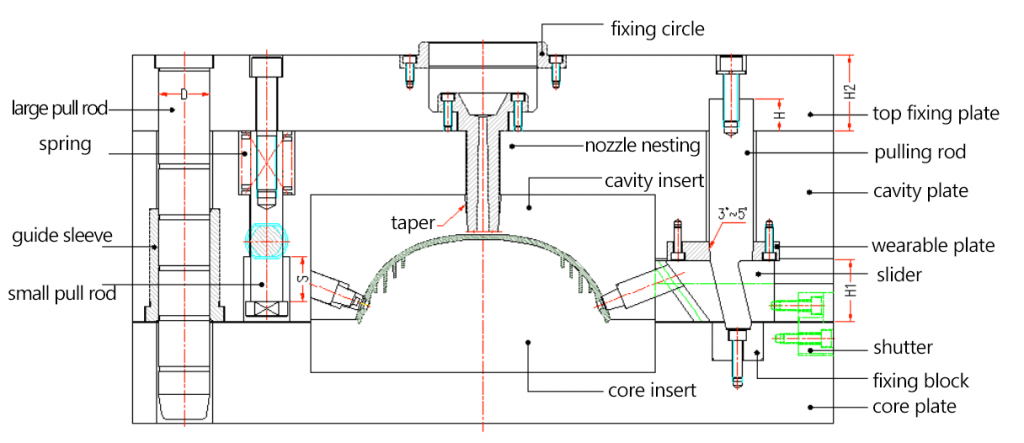

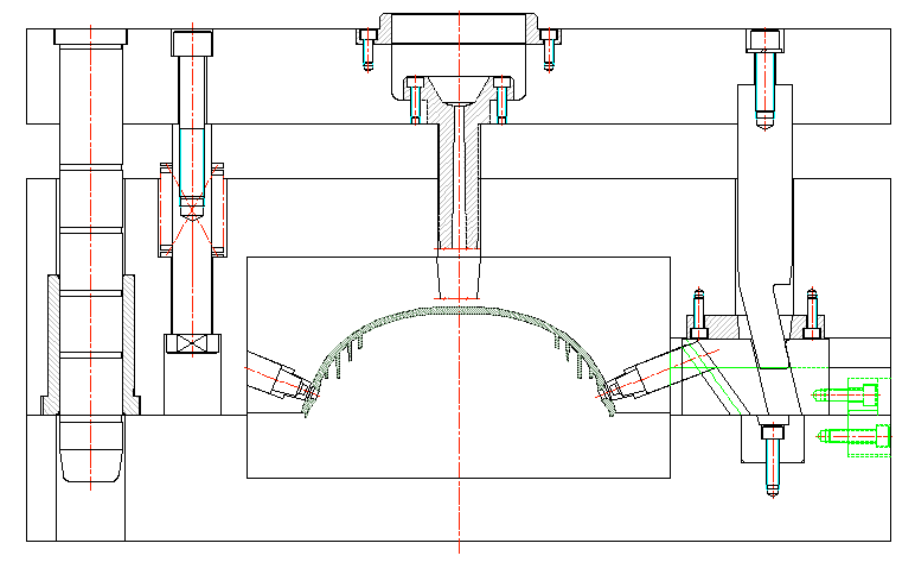

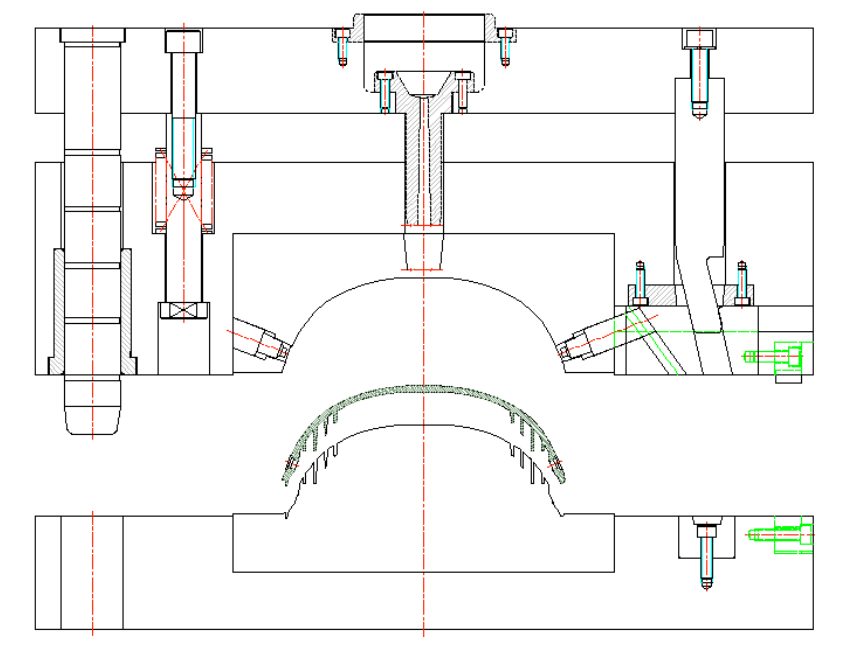

gst mold opening:

second mold opening:

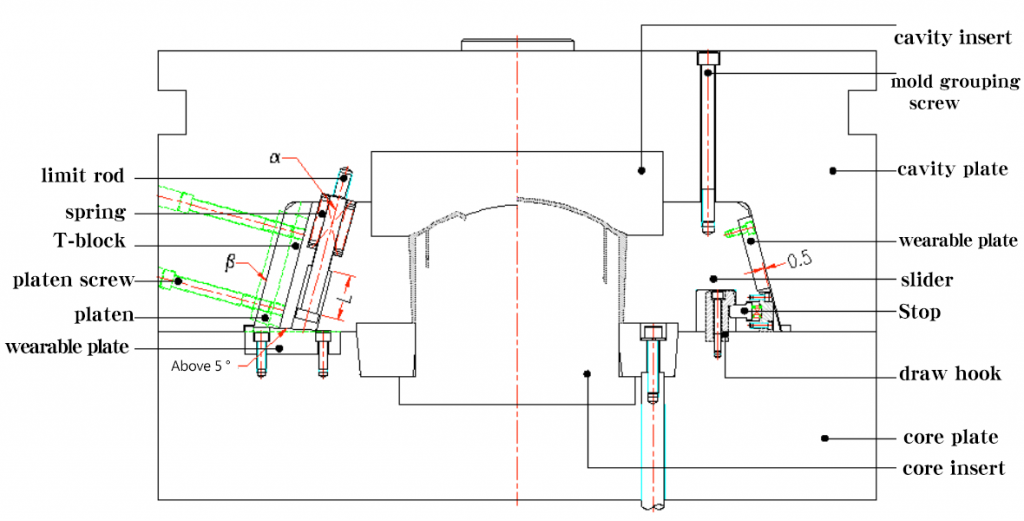

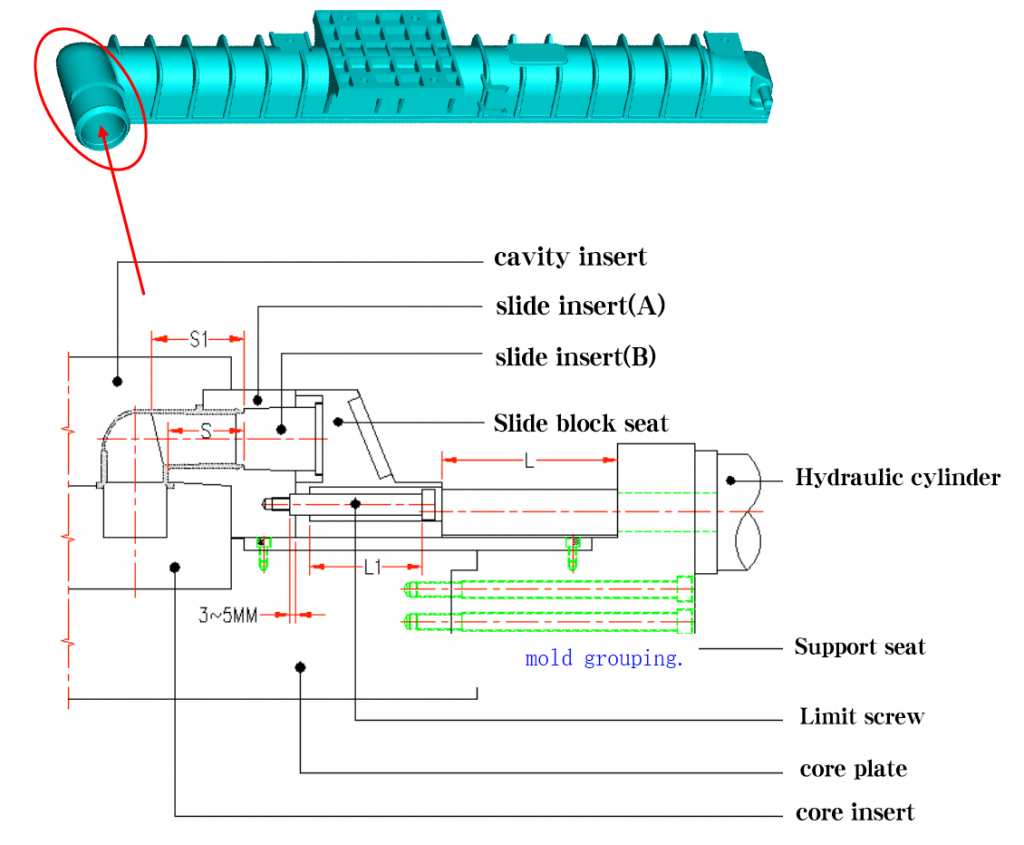

second mold Designing tips

a. Thickness of top clamping plate H2≧1.5D (D – diameter of large tie rod; hyperlink of large tie rod diameter calculation, three play mold large tie rod calculation; H2- thickness of top clamping plate).

b. Depth of pulling block inserted on the top clamping plate H≧2/3H2

c. There should has taper on SPRUE BUSHING head to fit for clamping and should be on the top clamping plate to avoid brush nozzle on the molding machine separating from SPRUE BUSHING and then result in brush, which is inconvenient to take out and affects next injection.

d.when pulling block inside the cavity plate, should reduce material.

e.The wearable plate should be 0.5mm higher than master mold plate to protect the taste mold plate and support the support pulling block to prevent it from distorting due to the external force.

f. Small pull rod limit stroke: S≦2/3H1 assist with mold clamping. (H1 – height of the slider)

g. It is best to have fixed block on the front of pole, easy to adjust and processing, consist three point bearing, increase the strength of pulling block.

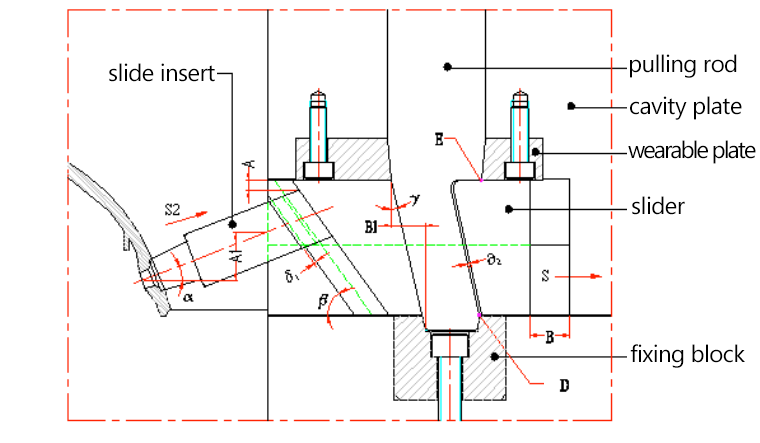

h.To make the wearable block assemble smoothly, E point should on the right of D point. Shown as below:

I. When assembling slide base and pulling block, need to notice about the relationship between size B and B1, it shoulbe B>B1, while in order to assemble smoothly, can also dig through the rear mold located after the slide base.

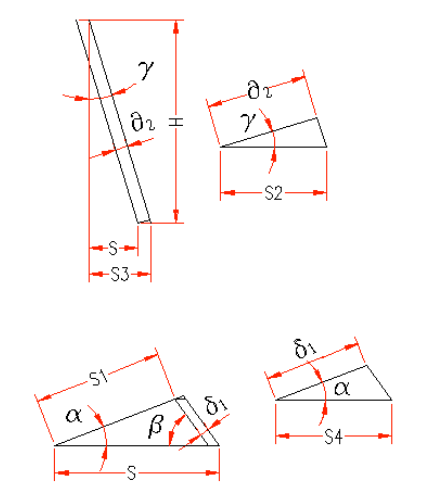

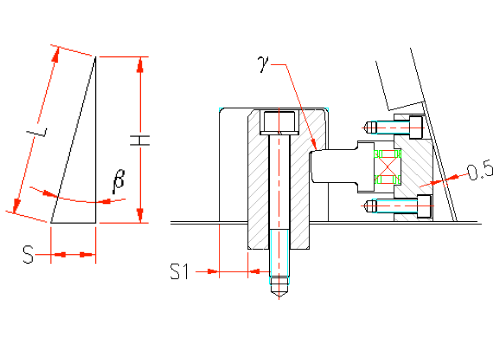

Dos and don’ts & calculation formula of double “T” groove

Shown as above:

S3=H*tgγ;

(H – the decreased height of slide block which is the small pull rod stroke; γ – the angle of pulling block)

S2=δ2*cosγ;

(δ2 – the space between pulling block and slide block, normally is 0.5mm)

S=S3-S2=H*tgγ-δ2*cosγ=(H*sinγ-δ2)/cosγ;

(S — horizontal moving distance of slide block)

S4=δ1/cosα;

(δ1 – slider insert and space between sliders;α -tilt angle of slider insert)

S1=(H*sinβ-δ1)/sin(α+β);

(β – space between grooves,normally is 0.5mm;S1- distance of slider insert out from the undercut)

Dos and donts:

a. Assemble requirements: assemble the slider insert and inclined insert hole, it should notice the relationship between the size A and A1, should be A>A1.

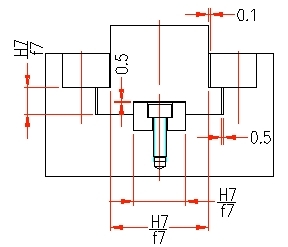

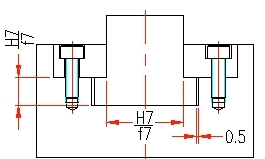

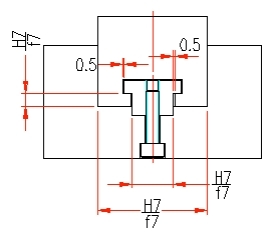

b. Double “T” groove tolerance, shown as below:

Case of Assemble matters

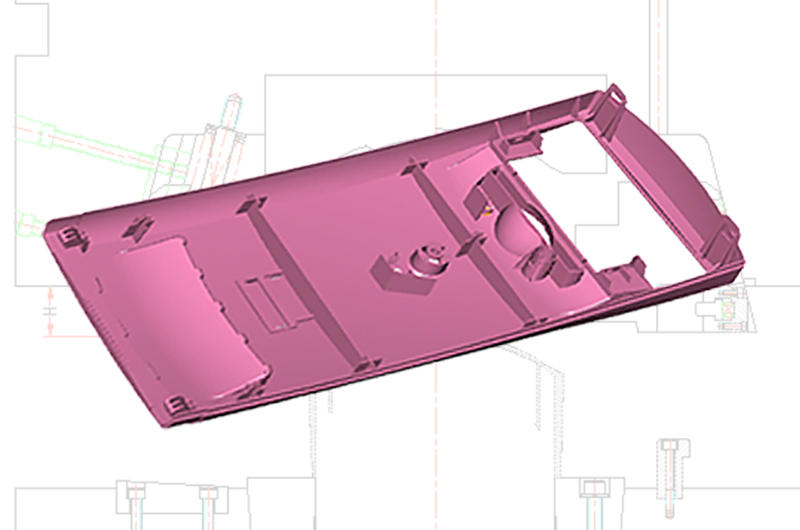

Die sketch

pic above :

Slide insert can be put inside the core insert without problems, required S1>S or open the core plate.

β=α+2°~3° (easy to open mold and reduce scratches)

H≧1.5D H is diagonal brace pin matching length; D is diameter of diagonal brace pin)

Double “T” groove structure model:

Double “T” groove structure model:

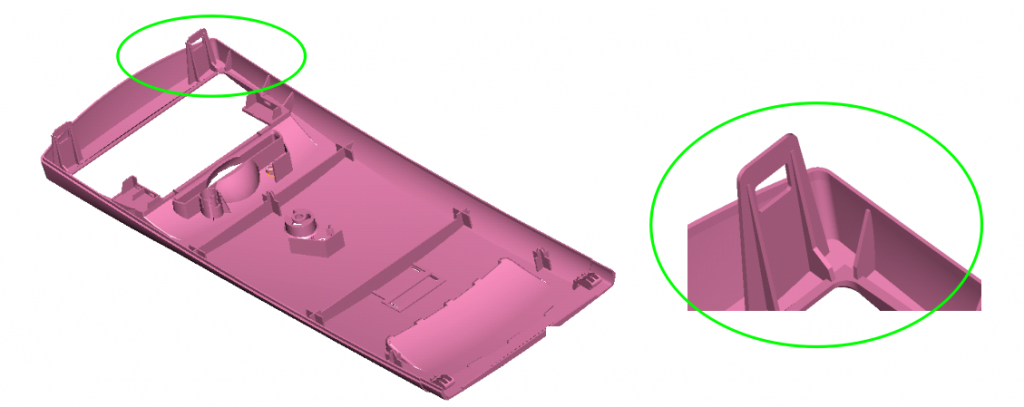

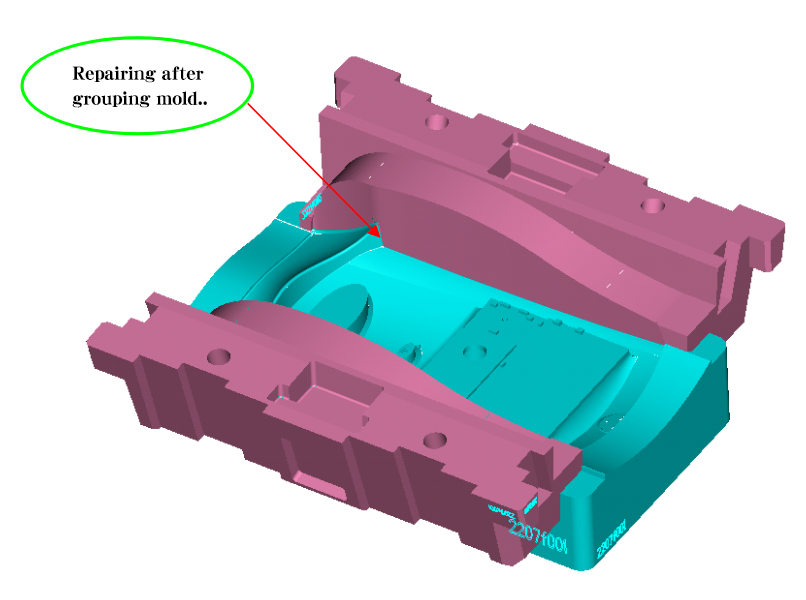

Cavity explosive slider

applicable situations of explosive slide block

Generally, forming on the cavity side and large slider forming area, especially using slider when the cavity side is very deep.

Explosive slider as blow pic shows:

mold opening state:

Stroke calculation:

Shown in the pic below:

S=L*sinβ (β- “T” groove angle;L stroke along the “T” groove direction; S – distance of slide block horizontal movement)

H=L*cosβ (H distance of slide block vertical distance)

Design tips and notices of explosive slide block

Shown as the pic on the right:

a.bottom wearable plate needs bevel, reduce loss between slide block and core plate, normally takes 1.5˚~3˚, assemble location be at the 3 / 4 of the center of gravity of the slide block.

b.S1>S (S – distance of slide block horizontal movement)

c. the wearable plate on the back of slide block and should be 0.5 mm higher than slide block’s back.

e. The angle between block and grab hook γ> the wearable plate obliquity.

f.β=α (β is “T” groove angle;α is lmit rod angle)

g. T – block should be longer and 10 mm higher than cavity plate.

h. Slide block head should have die screw, easy to group the mold. Need to take down when testing mold

i. Lock T-block screw should be vertical to T block.

j. The spring at the head, should calculate the weight of slide block.

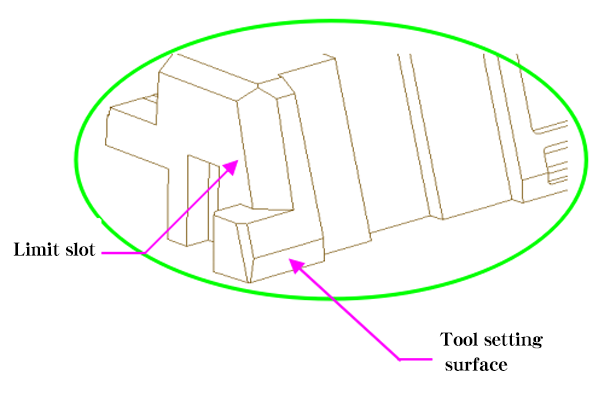

k. The back of the slide block should be tool setting plane.

l. Both flanks of slide block should have limit groove.

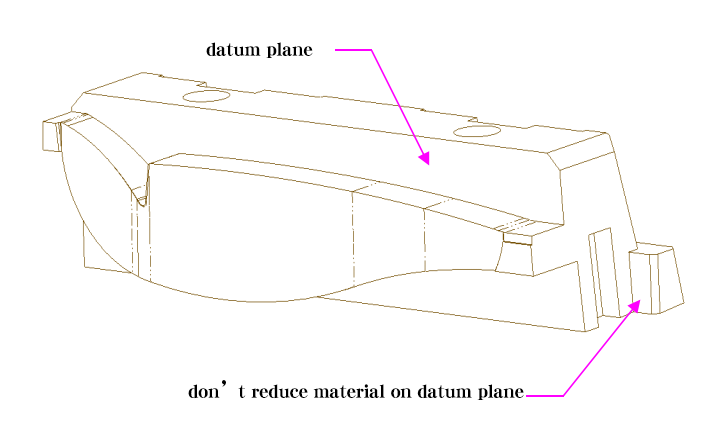

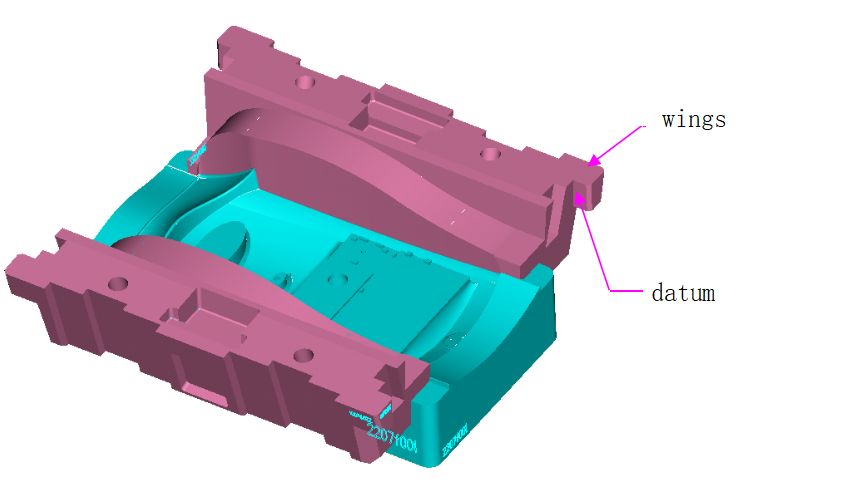

m. The slide block head must have datum plane to provide convenience for grouping mold. The processing base level is normally over 8mm.

n. Explosive slide block must have shoulder (wings for fixing) to provide convenience for grouping mold and also a base level is necessary, cannot reduce the material)

The assemble location depends on the location of the gravity of slide block.

Dos and don’ts of Extra deep explosive slide block

the guide rod should assemble from the cavity plate

a、Cavity plate should be embedded into the core plate,avoid the cavity plate outward lift, enhance the mold strength

b.wearable plates needed at the protruding side of cavity plate, avoid scratches, easy to adjust.

c. Other precautions are the same as above

Place ejector pin inside slider

Generally, for thick and deep products’ wall, the side of the wall has many core pulling holes. The core pulling force is strong, so when moving the slide block, the product might be distorted or scratched. To avoid these happening, we need to place the ejector pin inside the slide block to stop the distortion or scratches.

A. Place ejector pin inside slide block (example 1)

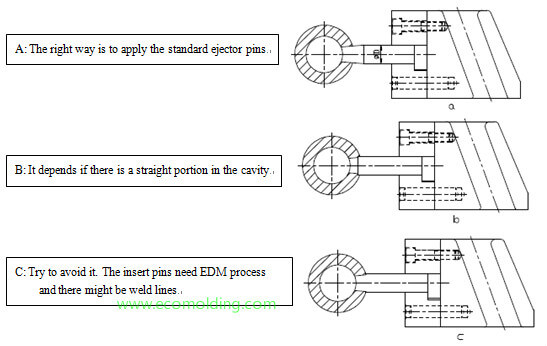

B. Two common ways to place the ejector pin inside slide block, shown as below:

Delay slider

1. The outside product pulling force is strong, avoid distortion.

2. Use delay slider to operate forced demolding.

The pic below is water pipe and water pipe delay diagram:

1st mold

Finishing state after 2nd mold opening

oblique slider

1. Application range of oblique slider Normally applied in the products with slider structure, at the same time, along the slider’s direction, the end product also has undercut, which indicates that we can apply oblique slider.

note:

Pic on the right is typical case of oblique slider

2. Oblique slider diagram:

3.internal slider

(1) use boss form (seen as below)

Use the form of diagonal brace pin (as shown below)

S1 = S + 1mm above(S, undercut distance;S1 distance of slider moving

S2=S1/cosβ (S2, horizontal distance of slider;β obliquity of slider)

S2=S3=(H1*sinα-0.5)/cosα (H1, relative vertical height; obliquity of diagonal brace pin ≦25)°

γ=α+2°~3°

H≧1.5D (D, diameter of diagonal brace pin; H, matching distance of diagonal brace pin)

*Detailed dimension calculation hyperlink oblique slider calculation*

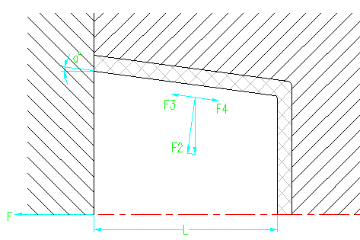

Calculation of core pulling force & strength checking

1. Calculation of core pulling force

After cooling, the plastic will be narrowing and shortening, including the die core and the other parts (like oblique tip, slider, insert etc)Therefore, we must consider the enclosed strength that end product impact on slider, stress state, see pic on the right

note:

F=F4*cosα-F3cosα=(F4-F3)*cosα

F—core pulling force(N);

F3—F2 lateral component(N)

F4— core pulling resistance(N);

α—obliquity of de-molding. as α is normally low, so cosα=1

That is F=F4-F3

But F2=F1-cosα

F3=F2tgα=F1cosα*tgα=F1*sinα

F4=F2*μ=μ-F1cosα

So F=F4-F3=μ*F1cosα-F1sinα=F1(μcosα-sinα)

F1——the enclosed strength that plastic on core (N)

F2—perpendicular to positive pressure on the surface of core(N)

μ—the friction coefficient between palstic and steel, normally is around 0.2

While F1=CLF.

The average circumference of core cross-section part which enclosed by plastic.

L—the distance of core part enclosed by plastic (CM)

F0—enclosed strength of unit area, normally 7.85~11.77MPA

Namely F=100CLF0(μcosα-sinα) (N)

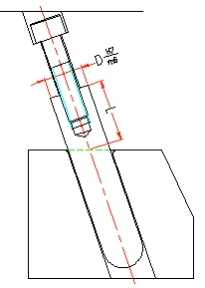

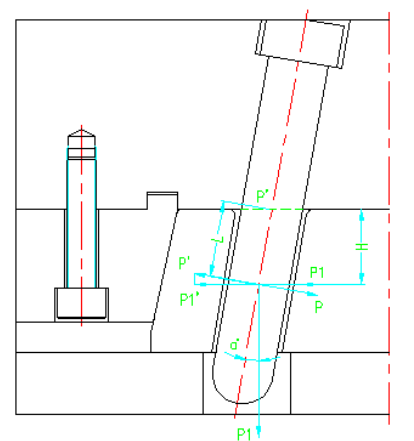

2. Diagonal bracing tip diameter checking:

The diameter of diagonal bracing tip is affected by many factors, like obliquity, length, and required de-molding distance. Thus, in designing, some parameters should be adjusted and matched to obtain the best result to make sure the slider to move smoothly. Calculation formula:

Note:P – maximum bending force on taper pin

L— bending moment

P1—core pulling resistance

H— distance from core pulling hole center to point A

α°—obliquity of taper pin

P2—mold opening force

From the pic we know:

P=P1/cosα (KN)

M curve=PL (KN)

Which is M curve≦[σcurve]*W (KN)

namely PL=[σ curve]*W (KN)

W—bending section coefficient

[σ curve]—permissible bending stress(for carbon steel – 13.7KN/CM2 (137MPA)

M curve—maximum moment on taper pin

Namely: W=(πd4/64)/(D/2)= πd3/32=0.1d3

0.1d3=pL/[σ]=PH/([σ]cosα)

0.1d3=pL/[σ]curve=PH/([σ]curve cosα)

D=3√(ph/0.1[σ]cosα (cm)

D=3√(ph/0.1[σ] curve cosα (cm)

3.size of pulling block section checking

The size of pulling block section checking is as same as the calculation of diagonal bracing tip. It only needs to alter the last step. Formula:

W=bh2/b

When b=2/3h, W=h3/9

h3/9=pL/[σ] curve =PH/([σ] curve cosα)

H=3√9PH/([σ] curve cosα) (cm)

When b=h, W=H3/b]

H=3√(6ph/[σ] curve*cosα) (cm)

h—long side of puling block section(cm)

b—short side of pulling block section(cm)

The sliders for plastic injection mold

===========================================

The slider for plastic injection mold

Basic Principles of the Slider

Due to the special requirements of a product, the mold release direction of a particular part may not be consistent with the mold opening direction of the injection molding machine (product undercut), the slider,also known as slide,is a mold mechanism that is developed to solve the issues with the undercut. The basic principle is to turn the vertical movement of mold opening / closing into a horizontal motion. In order to cope with the situation that the undercut is located in the core or cavity, different structural forms are developed:

Note:

To mold a product with a deep cavity, of which the side wall does not allow a draft angle, but requires a high gloss, the mold structure also needs to adopt slider mechanism.

Structural Composition of the Slide

The slide mechanism is usually comprised of the following basic components.

Note:

During slide operation, since the slide, the press plate, the wedge, the guide pin and the wear plate are subject to long-period wear, surface nitriding must be performed to minimize surface wear.

Design of the Angle Pin(Guide pin)

1: How the angle pin locks and where it is used

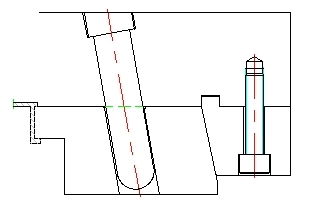

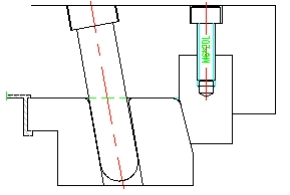

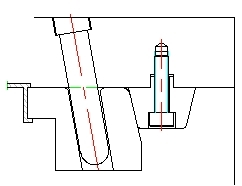

2: How the Guide Block Moves and Its Design Points

The mold opening action of the injection molding machine is leveraged to make the guide block and the slide move relatively, and surface B engages with the slide to make it move in two directions – the mold opening direction and the horizontal direction, so that it disengages with the undercut. The guide block acts as an angle pin when the mold opens, and as a locking block during mold closing.

See the figure as below:

β = α ≦ 25° (α is the tilt angle of the guide block);

H1 ≧ 1.5W (H1 is the corresponding length);

S = T + 2-3mm (S is the horizontal travel distance of the slide; T is the undercut of the finished product);

S = H * sinα-δ / cosα(δ is the gap between the angle pin and the slide, generally is 0.5MM;

H is the vertical distance of the guide block in the slide);

C is the stop surface, so generally a stop block is not needed when the guide block is used (gaps not allowed).

How the Slider Locks

Since great pressure is generated during the plastic injection molding process of a product, to prevent the slider from being displaced by the pressure, which may affect the dimensions and appearance of the finished product (such as flashing), the slider should be locked.

Commonly seen locking methods are shown below:

How the Slider Is Located

The slide travels a certain distance during mold opening. Therefore, to guarantee safe slider return, the slider must be equipped with a locking device, which needs to be flexible and reliable to ensure that the slide stays where it is. However, in some special cases, a locking device is not necessary, such as the slider that moves from left to right. But to ensure safety, it is better to have a locking device installed.

How to Connect the Slider Insert

The connection method for the slider insert is determined by the finished product, since it may vary with different products. The specific connection methods are shown as follows:

Sliding Guide of the Slide

Sliding guide(sliding rail) has to ensure that the slider moves smoothly and stably, so the slide does not get stuck or bounce during the plastic injection molding process, or product and mold service life will be affected. Sliding guide has to ensure that the slider moves smoothly and stably, so the slider does not get stuck or bounce during the plastic injection molding process, or product and mold service life will be affected.

The commonly used sliding guides are shown below:

=======================================

Injection mold sliders designing

1. When designing the injection mold sliders, the biggest clearance between the slider and the product should be at least 2 – 3mm.

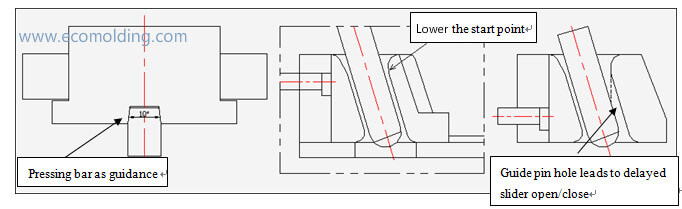

- The inclination of sliders should be kept between 15 and 25 degrees, and the inclination of the guide pin should be 2 degrees smaller that of the wedge. The available diameters of the guide pin are 6mm, 8mm, 10mm and 12mm, with the min and max values being 6mm and 12mm respectively. If a slider width is larger than 60 mm, deployment of 2 angle pins needs to be considered; if the width exceeds 80mm, a guide bar needs to be placed under the slider in middle.

- If the injection mold sliders is too high, the starting point of the angle pin hole needs to be lowered, so as to ensure smooth travel of the slider. If slider open/close time needs to be delayed, the diameter of the guide pin hole will need to be enlarged.

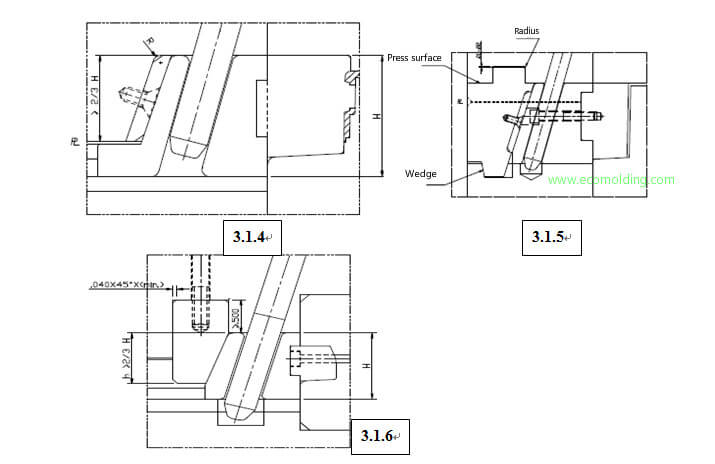

- When the injection mold sliders are deeper in the cavity than its own length, a wedge will not be necessary. The inclination can be designed on plate A directly. A R3 is required at the bottom. Besides, the slider doesn’t need a wear block.

- When depth of the slider is mainly in the core, a wedge will be needed; if the part profile surface contacting the slider is large, or there’s kiss off or shut off on the slider, a reversed wedge should be applied and the inclination should be 10 degrees or above;

- If the part profile surface contacting the slider is small, the slider can be designed as shown in Fig. 3.1.6, and the height of the wedge surface should be higher than 2/3 of the slider height.

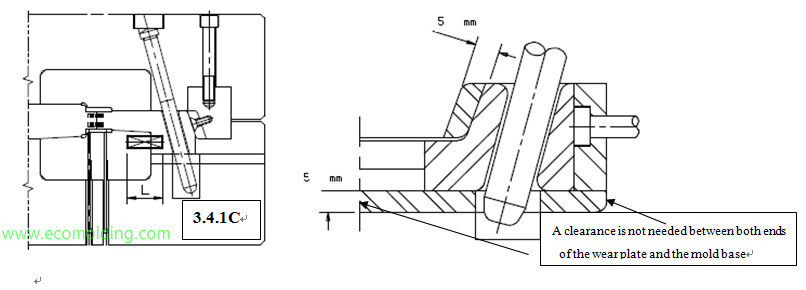

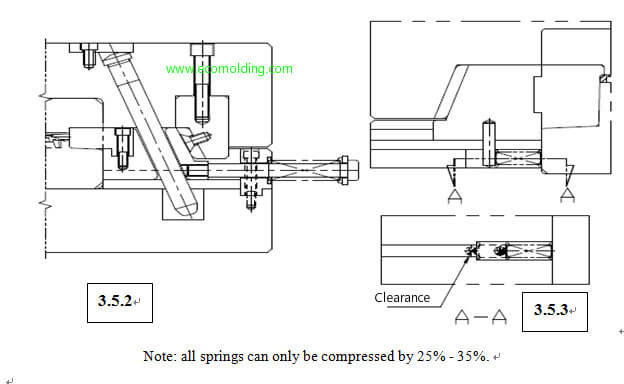

- The wear plate of the mold slider employs the 2510 steel, of which the hardness reaches up to HRC50°-52°. For all sliders with a thickness of over 50.0mm, wear blocks should be placed on the base and the back. These wear plates measure 5mm in thickness, and are 0.50mm higher than the mold base. And for all the sliders, a clearance is not needed along the travel direction of the slider (as shown in the following Fig.)

- The width and height of the slider clamp – made from the 2510 steel with a hardness of up to HRC50-52 – are 20mm and 20mm respectively, while the length is dependent on slider.

- Mold Slider Return and Fastening Method

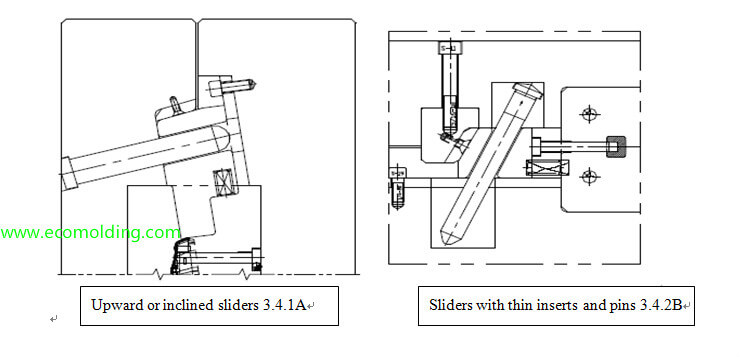

For upward (including inclined ones) sliders, there are raised fine inserts and pins. When there’s an ejector pin under the slider, a spring can be applied to facilitate return.

- Requirements for Spring Location Design

- Spring is built in the mold core and the slider (see 3.4.1A, 3.4.1B and 3.4.1C)

- If the travel distance of the slider is long with an installation length of over 50mm, the spring may be mounted outside.

- Air/Hydraulic Cylinder driving

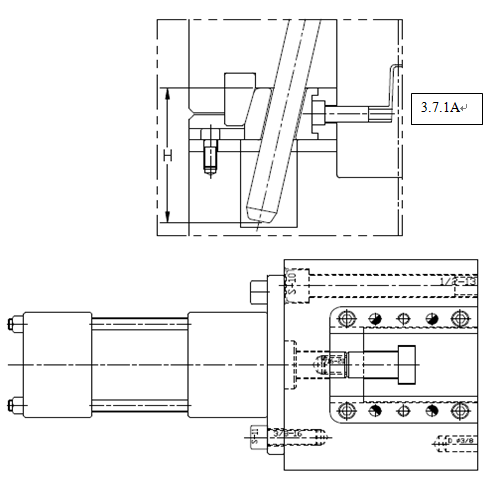

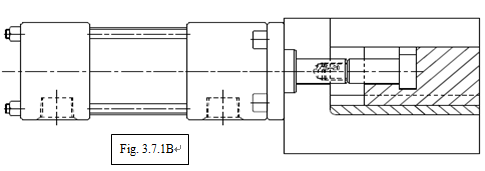

If the height of the guide pin is larger than 100mm (see Fig. 3.7.1A) and the cavity slider needs to be lifted before A and B plates separate from each other, a Air/Hydraulic cylinder may be applied to drive it (see Fig. 3.7.2B).

- Design Standard of Slider Inserts (Pins)

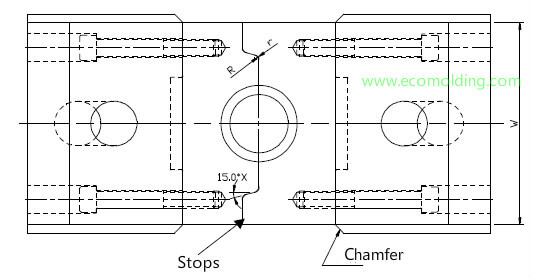

- Design Standard of Slider Stops

For the undercut of a circular product with sliders on 4 sides, a stop needs to be mounted to the slider insert. It is better to design a separate stop for each individual product if there are multiple products in a single mold.

================================

没有评论:

发表评论